Structural Health Monitoring Market Size 2025-2029

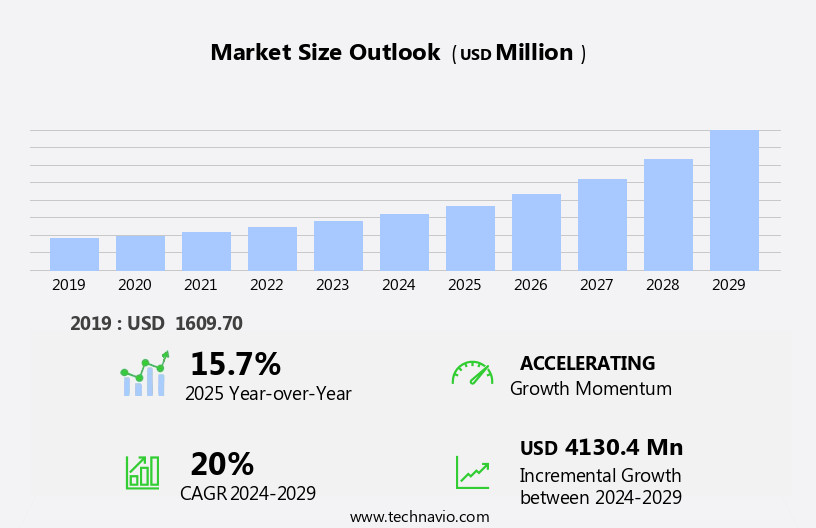

The structural health monitoring market size is forecast to increase by USD 4.13 billion, at a CAGR of 20% between 2024 and 2029.

- The Structural Health Monitoring (SHM) market is experiencing significant growth, driven by the increasing need for infrastructure maintenance and safety. With the aging infrastructure worldwide, there is a growing awareness of the importance of proactively monitoring the condition of structures to ensure their longevity and safety. This is particularly relevant in industries such as construction, transportation, and energy, where the consequences of structural failure can be catastrophic. Another key driver for the SHM market is the advent of Internet of Things (IoT) technology. IoT sensors enable real-time monitoring of structural health, providing valuable data for predictive maintenance and early detection of potential issues.

- This not only enhances safety but also reduces downtime and maintenance costs. However, the market faces challenges, including budgetary constraints, which can limit the adoption of SHM systems, particularly in smaller organizations and projects. Despite this, the potential benefits of SHM are compelling, making it an attractive area for investment and innovation. Companies seeking to capitalize on this market opportunity should focus on developing cost-effective solutions that provide real-time data and actionable insights, while also addressing the challenges of installation, integration, and maintenance.

What will be the Size of the Structural Health Monitoring Market during the forecast period?

Explore in-depth regional segment analysis with market size data - historical 2019-2023 and forecasts 2025-2029 - in the full report.

Request Free Sample

The structural health monitoring (SHM) market continues to evolve, driven by the increasing demand for real-time monitoring and condition-based maintenance in various sectors. Environmental factors, such as humidity and temperature effects, significantly impact the structural integrity of buildings, civil infrastructure, offshore structures, and aerospace structures. SHM applications extend to damage identification, data acquisition systems, and decision support systems, which utilize advanced software algorithms, machine learning, and sensor fusion. Cloud-based platforms facilitate remote monitoring and data visualization, enabling asset management and cost optimization. Low-power sensors and wireless communication enable the deployment of SHM systems in remote and hard-to-reach locations. Vibration monitoring, acoustic emission testing, and fiber optic sensors are integral to the early detection of cracks and fatigue analysis.

Power plants and industrial facilities require continuous monitoring for data validation, quality control, and risk assessment. SHM systems ensure data integrity and long-term stability, providing valuable insights for maintenance procedures and life cycle assessment. Sensor reliability, accuracy, and integration are crucial considerations for effective SHM implementation. Data security and expert systems are essential components of SHM systems, ensuring the confidentiality and authenticity of data. The ongoing development of SHM technologies offers significant potential for the monitoring of tunnels, pipelines, bridges, wind turbines, and nuclear power plants. The evolving market dynamics reflect the continuous unfolding of innovative applications and solutions in the realm of structural health monitoring.

How is this Structural Health Monitoring Industry segmented?

The structural health monitoring industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Component

- Hardware

- Software

- Services

- Connectivity

- Wired

- Wireless

- Application

- Civil infrastructure

- Aerospace

- Energy

- Defense

- Others

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- Italy

- UK

- APAC

- China

- India

- Japan

- South Korea

- Rest of World (ROW)

- North America

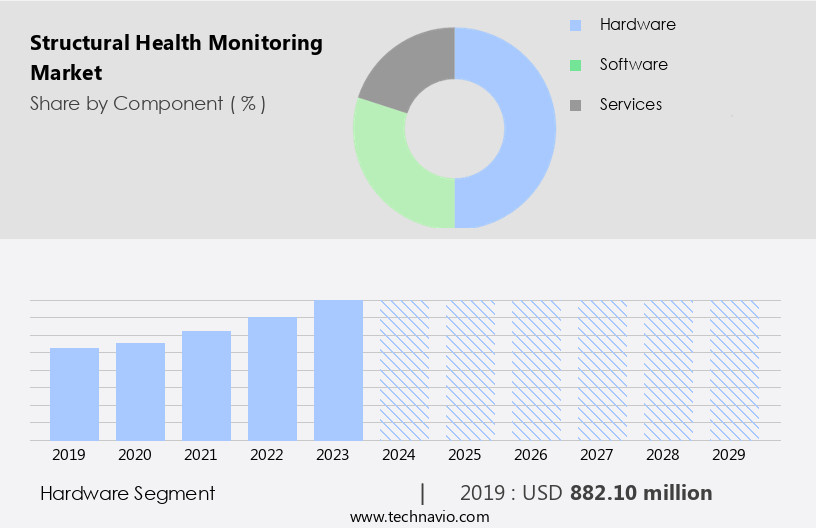

By Component Insights

The hardware segment is estimated to witness significant growth during the forecast period.

The market encompasses various sectors, with hardware being a significant component. Hardware in this context refers to the physical devices and instruments used to assess the structural health of infrastructure, buildings, bridges, and other civil structures. Sensors are a vital hardware segment, as they capture essential data on structural behavior, including strain, vibration, temperature, humidity, and corrosion. Installation techniques are crucial for sensor reliability and accuracy, ensuring proper placement and calibration. Real-time monitoring is facilitated by software algorithms, enabling prompt identification of anomalies and damage. Offshore structures, such as oil rigs and wind turbines, require specialized sensors for monitoring environmental factors like temperature, humidity, and wave action.

Corrosion monitoring sensors help detect and prevent damage in industrial facilities and civil infrastructure. Strain gauges, a type of sensor, measure deformation and stress in structures, while alert systems provide immediate notifications of potential issues. Cloud-based platforms facilitate data acquisition, storage, and analysis, allowing for big data analytics and machine learning applications. Low-power sensors and wireless communication enable remote monitoring, reducing the need for frequent on-site inspections. Fiber optic sensors offer high precision and long-term stability, making them suitable for applications like bridge monitoring and fatigue analysis. Sensor integration, data security, and expert systems are essential for ensuring data integrity and accurate decision-making.

Cost optimization and life cycle assessment are crucial considerations in the deployment and maintenance of structural health monitoring systems. Data validation and quality control procedures help maintain sensor accuracy and reliability. Environmental factors, such as temperature and humidity, can impact sensor performance and data interpretation. Damage identification and risk assessment are critical applications of structural health monitoring, with applications ranging from civil infrastructure to aerospace structures and nuclear power plants.

The Hardware segment was valued at USD 882.10 billion in 2019 and showed a gradual increase during the forecast period.

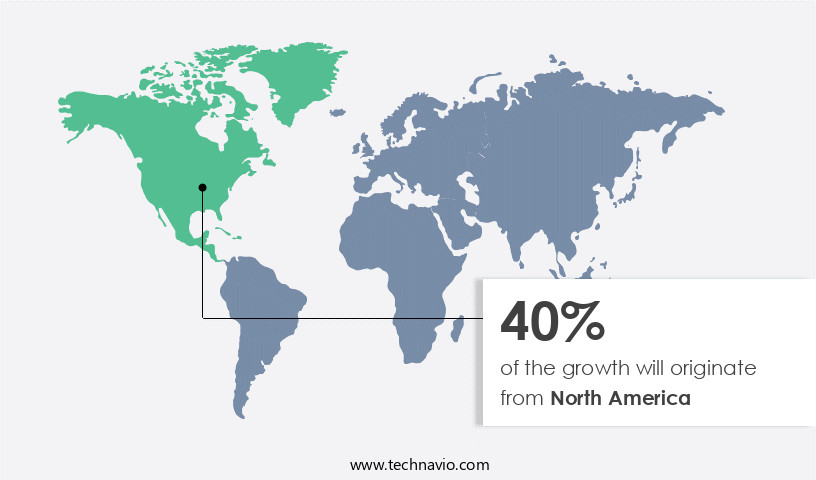

Regional Analysis

North America is estimated to contribute 40% to the growth of the global market during the forecast period.Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The market in North America is experiencing significant growth, driven by several key factors. The increasing adoption of advanced monitoring services by industries such as IT, apparel and textile, FMCG, and consumer durables is a major contributor. These industries are witnessing an expansion in the number of office buildings in regions like the Southeast, Mideast, Far West, Great Lakes, and Southwest. In addition, there is a trend towards replacing conventional management services with third-party structural health monitoring providers. Furthermore, the growth of end-user industries and government initiatives for implementing structural health monitoring are also fueling market growth. Advanced technologies such as artificial intelligence, real-time monitoring, machine learning, and big data analytics are transforming the industry.

These technologies enable condition-based maintenance, predictive analysis, and remote monitoring, enhancing the overall efficiency and reliability of structures. Installation techniques for sensors, including fiber optic sensors, strain gauges, and acoustic emission testing, are continually improving, ensuring greater sensor reliability. Structural analysis, including temperature effects, humidity effects, and crack detection, is becoming more sophisticated, allowing for early damage identification. Data visualization tools and decision support systems facilitate data interpretation and data-driven insights. Sensor integration, data security, and cost optimization are critical considerations for asset management in various sectors, including civil infrastructure, offshore structures, wind turbines, and industrial facilities. Long-term stability, signal processing, and sensor fusion are essential for ensuring the accuracy and effectiveness of health monitoring systems.

Nuclear power plants and aerospace structures also benefit from these advanced monitoring solutions. Overall, the market in North America is poised for continued growth, driven by technological advancements, increasing industry adoption, and government initiatives.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

The market encompasses innovative technologies and solutions designed to assess the condition of infrastructure assets, ensuring their safety and longevity. This market caters to various industries, including transportation, construction, energy, and civil engineering. Key players offer advanced sensors, monitoring systems, and data analysis tools to detect anomalies, predict failures, and optimize maintenance. Structural health monitoring systems utilize technologies like IoT, AI, and machine learning for real-time data collection and analysis. These solutions enable proactive maintenance, reducing downtime and maintenance costs, while ensuring public safety and infrastructure reliability. Additionally, regulatory compliance, increasing demand for smart infrastructure, and growing awareness of risk mitigation are key market drivers.

What are the key market drivers leading to the rise in the adoption of Structural Health Monitoring Industry?

- The escalating demand for infrastructure maintenance and safety measures serves as the primary market catalyst.

- The market is experiencing significant growth due to the increasing importance of asset management in various industries, including civil infrastructure, industrial facilities, and renewable energy. Structural health monitoring solutions, such as those used for wind turbines, tunnel monitoring, and pipeline monitoring, leverage advanced technologies like big data analytics, machine learning, and data interpretation to provide real-time data on the condition of critical infrastructure. This data is crucial for maintaining the safety and integrity of these assets, as well as for implementing effective maintenance procedures. Safety concerns are a major driver for the adoption of structural health monitoring systems.

- Infrastructure failures can result in catastrophic consequences, including loss of life, property damage, and economic disruptions. By continuously monitoring the health of infrastructure, potential issues can be identified and addressed before they escalate into costly and dangerous problems. Additionally, temperature effects and crack detection are critical aspects of structural health monitoring, as they can indicate underlying issues that may lead to infrastructure failure. Machine learning algorithms and data validation techniques are used to ensure the accuracy and reliability of the data generated by these systems. Quality control measures are also essential to ensure that the data is interpreted correctly and that maintenance procedures are carried out effectively.

- Overall, the market is poised for continued growth as the need for infrastructure maintenance and safety becomes increasingly prioritized.

What are the market trends shaping the Structural Health Monitoring Industry?

- The IoT's emergence is shaping the future of structural health monitoring as a significant market trend. In this context, IoT technology enhances infrastructure surveillance, offering enhanced efficiency and accuracy.

- The market has witnessed significant growth due to the integration of advanced technologies such as Internet of Things (IoT) and Industry 4.0. IoT networks consist of various devices, including sensors, thermostats, and actuators, which are interconnected over the Internet. These devices collect and evaluate data to optimize energy usage and implement predictive maintenance, leading to reduced operational costs and enhanced productivity. Moreover, IoT technologies enable remote monitoring of environmental factors affecting aerospace structures, power plants, and other critical infrastructure. Damage identification is facilitated through techniques such as vibration monitoring, acoustic emission testing, and signal processing. Data acquisition systems and cloud-based platforms ensure data integrity and long-term stability.

- Sensor fusion and decision support systems further enhance the accuracy and efficiency of damage identification. In summary, the market is driven by the adoption of IoT and Industry 4.0 technologies, which offer benefits such as energy efficiency, predictive maintenance, and remote monitoring. These innovations have transformed the way organizations manage their critical infrastructure, ensuring improved safety, reliability, and sustainability.

What challenges does the Structural Health Monitoring Industry face during its growth?

- Budgetary constraints posing a significant challenge, the industry's growth is adversely affected.

- Structural health monitoring (SHM) is a critical aspect of maintaining the integrity and safety of infrastructure, particularly in industries such as nuclear power. SHM utilizes advanced technologies like fiber optic sensors for fatigue analysis and expert systems for risk assessment. However, small organizations, even in developed economies, face budgetary constraints that prevent them from procuring services from established SHM providers. This results in the deployment of less accurate sensors and sensor integration challenges, leading to increased maintenance and operation costs.

- Furthermore, labor costs pose another significant challenge to the growth of the SHM market. To mitigate these issues, organizations are focusing on cost optimization through sensor deployment strategies, life cycle assessment, and data logging using wireless communication and data security measures. These efforts aim to improve overall SHM capabilities while reducing costs and enhancing profitability.

Exclusive Customer Landscape

The structural health monitoring market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the structural health monitoring market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, structural health monitoring market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Campbell Scientific Inc. - This company specializes in advanced structural health monitoring, utilizing cutting-edge technologies like the VSPECT system. Our solutions ensure infrastructure durability, enhancing safety and efficiency through real-time data analysis and predictive maintenance.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Campbell Scientific Inc.

- CGG SA

- COWI Holding AS

- Digitexx Systems Ltd.

- Geosense Ltd.

- Hottinger Bruel and Kjaer GmbH

- James Fisher and Sons Plc

- Kinemetrics Inc.

- LiveHooah Technologies Pvt. Ltd.

- MachineSense LLC

- Mistras Group Inc.

- National Instruments Corp.

- Nova Ventures Group Corp.

- Ramboll Group AS

- RST Instruments Ltd.

- Sisgeo S.r.l.

- STRUCTURAL MONITORING SYSTEMS plc

- Vinci

- Xylem Inc.

- Yokogawa Electric Corp.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Structural Health Monitoring Market

- In January 2024, Sensys GmbH, a leading structural health monitoring (SHM) solutions provider, announced the launch of its new wireless SHM system, named "WireFree," at the World Economic Forum in Davos, Switzerland (Sensys GmbH press release). This innovative system enables real-time monitoring of infrastructure health without the need for wired connections, expanding the company's product portfolio and catering to the growing demand for wireless SHM solutions.

- In March 2024, Hexagon AB, a global technology company, entered into a strategic partnership with Geokon, Inc., a geotechnical instrumentation and monitoring solutions provider, to integrate Geokon's sensor technology into Hexagon's SHM solutions (Hexagon AB press release). This collaboration aims to enhance Hexagon's offering by incorporating Geokon's expertise in geotechnical monitoring, expanding their market reach and strengthening their position in the SHM industry.

- In May 2024, StrainSense Technologies, a start-up specializing in fiber optic sensing technology, secured a USD10 million Series A funding round led by Khosla Ventures and Horizons Ventures (StrainSense Technologies press release). The investment will support the company's research and development efforts, aiming to advance their fiber optic sensing technology for SHM applications and expand their market presence.

- In April 2025, the European Union (EU) published a new regulation, the European Infrastructure and Projects Banking Union Regulation, which includes provisions for mandatory structural health monitoring for all new infrastructure projects receiving EU funding (European Commission press release). This regulatory initiative is expected to significantly boost the demand for SHM solutions in Europe, creating new opportunities for market players and contributing to the growth of the global SHM market.

Research Analyst Overview

- The Structural Health Monitoring (SHM) market encompasses various technologies and techniques aimed at assessing the health and integrity of structures, from buildings and bridges to aircraft and wind turbines. Key market trends include the integration of advanced technologies such as root cause analysis, system identification, and probability of failure prediction through modal analysis and ultrasonic testing. Edge computing, augmented reality (AR), and virtual reality (VR) are transforming inspection processes, enabling real-time data analysis and visualization. Training and education in these technologies are essential for industry professionals, ensuring compliance with regulatory standards and adherence to industry best practices.

- Lifecycle cost analysis, risk management, and compliance management are crucial aspects of SHM, with data analytics dashboards and reporting and analytics playing a significant role in decision-making. Smart sensors, embedded sensors, and non-destructive testing (NDT) techniques like dye penetrant testing, magnetic particle testing, and radiographic testing are essential for continuous monitoring and predictive maintenance. Reliability analysis and corrective maintenance are also essential components, with the integration of digital twins, 3D modeling, and blockchain technology enhancing data security and traceability. Support and maintenance services are vital to ensure optimal performance and extend the life cycle of SHM systems.

Dive into Technavio’s robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Structural Health Monitoring Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

209 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 20% |

|

Market growth 2025-2029 |

USD 4130.4 million |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

15.7 |

|

Key countries |

US, Germany, China, UK, Canada, France, Italy, Japan, India, and South Korea |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Structural Health Monitoring Market Research and Growth Report?

- CAGR of the Structural Health Monitoring industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across North America, Europe, APAC, South America, and Middle East and Africa

- Thorough analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the structural health monitoring market growth of industry companies

We can help! Our analysts can customize this structural health monitoring market research report to meet your requirements.